Solar PV module technology is experiencing rapid advancements, continuously delivering improvements that are transforming the industry. However, assessing the long-term reliability of these changes is no easy task, considering modules are expected to perform reliably over decades. To address this critical issue, Sara Fall and Jarett Zuboy from NREL have developed a process to quickly identify and tackle potential reliability issues before they impact the market.

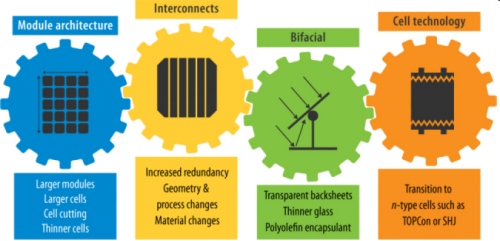

In a recent publication in the IEEE Journal of Photovoltaics, NREL researchers highlighted eleven key technology trends within four categories – module architecture, interconnects, bifacial technology, and cell technology. One notable example discussed in the paper is the transition from monofacial to bifacial PV module designs. While PV modules have historically demonstrated high reliability, continuous evolution in technology could introduce new reliability challenges.

As part of the Durable Module Materials (DuraMAT) Consortium, the researchers emphasize the importance of anticipating and mitigating module reliability risks. Teresa Barnes, the director of the Consortium, stresses the need to address future reliability concerns related to novel materials and designs that have not undergone extended field testing.

By synthesizing information from various sources, including market reports, interviews, and peer-reviewed literature, the researchers aim to bridge academic and market concerns to capture the evolving landscape of PV module technology. The collaboration with industry experts and researchers enables a comprehensive analysis of technology trends and their reliability implications.

Four key categories of PV trends – module architecture, interconnects, bifacial technology, and cell technology – are explored to understand the drivers, deployment projections, and reliability impacts of each trend. The switch from monofacial to bifacial designs, for instance, presents unique reliability considerations, such as potential-induced degradation mechanisms on the backside of bifacial modules.

Addressing the complexity of multiple interrelated technology trends, the researchers recommend a holistic approach to ensure module quality keeps pace with rapid technological changes. The PV reliability learning cycle, encompassing field diagnostics, failure analysis, and predictive modeling, plays a crucial role in continuous improvement and quality assurance.

While the published article focuses on crystalline silicon modules, the team plans to extend their analysis to include thin-film technologies in a follow-up publication. By staying ahead of the curve and anticipating potential reliability risks, NREL researchers aim to drive innovation and enhance the overall reliability of PV modules.

To delve deeper into the assessment of new photovoltaic module reliability risks and projected technological changes, readers can access the full article in the IEEE Journal of Photovoltaics. For more information, readers can contact the authors, Jarett Zuboy and Teresa Barnes, for insights and updates on the latest advancements in PV module technology.

By prioritizing proactive measures to address reliability concerns and leveraging the PV reliability learning cycle, NREL researchers are at the forefront of ensuring the continued advancement and reliability of solar PV module technology. With a focus on staying ahead of industry trends and mitigating potential risks, NREL continues to drive innovation in the renewable energy sector.